In press-locked gratings, both the bearing bars and the filler bars are made of flat material and are available from 20 to 150 mm grating height, in numerous mesh sizes.

For more than 60 years, we have been supplying individual requirements quickly, reliably and without any express surcharge.

Pressed gratings can be produced in different anti-slip designs from R9 to R13.

All common standard stair treads and gratings as standard sizes, are available from stock at short notice.

Pressed steel gratings are used for:

- Industrial platforms

- heavy duty gratings

- walkways

- facade gratings

- railing infill

- Stair treads and landings

Panne grating stair treads are characterised by safe accessibility, weather resistance and flexible application possibilities.

In addition to the comprehensive stock programme, we also manufacture grating stair treads in individual dimensions and mesh sizes.

All DIN lengths are available from stock in mesh sizes 30x30 mm and 30x11 mm.

Grating stair treads are available in steel, aluminium and stainless steel.

For your safety, you will receive a detailed stair plan before production!

Panne INDURO Aluminium gratings can be used to realise your most demanding projects.

Construction

INDURO aluminium gratings are manufactured in a hydraulic high-pressure pressing process. Through this, the filling bars are inseparably connected with the bearing bars, so that the grating can withstand the highest loads. This results in better flatness for long gratings.

Material:

INDURO aluminium gratings are made exclusively of the material EN AW 6060 (Al Mg Si 0.5). Bearing and filling bars are made of extruded profiles.

Surface treatment:

- Untreated (raw)

- Anodised E6 / EV1

- Powder coated according to RAL

No weldings are required in the grating surface due to the indissoluble node connections.

This special manufacturing process results in a visually appealing grating with high stability and flexible application possibilities.

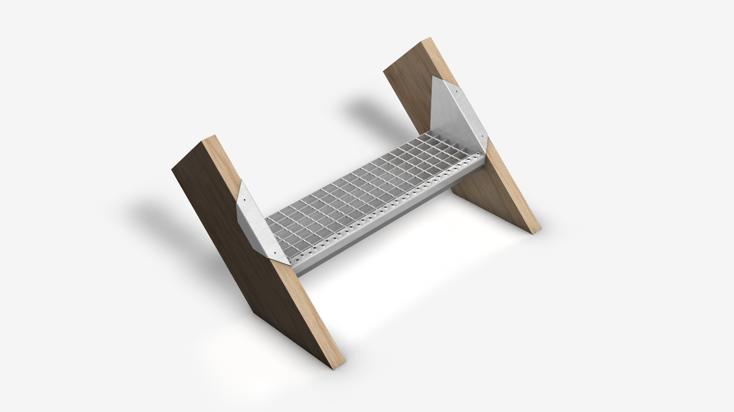

Nailing steps are a special form of stair steps that are used as a transitional solution in raw construction.

The step covering consists of anti-slip pressed grating type "SF", with mesh width approx. 30/30 mm, slip class R12.

With these grating stair steps, standard building planks can be used as stair stringers.

The nailing steps are hooked into the vertical planks and fastened on both sides with 2 nails each.

They are available in 3 different widths.

The angle of inclination is either 37° or 45°.

Available in hot-dip galvanised steel.